The machine has the advantages of compact structure, small footprint, convenient operation and low energy consumption. The main parts have high processing precision requirements, strong crushing ability, high efficiency, and high wear resistance of the working surface. The number of grinding mesh is stepless adjustment, no clumping after grinding, and the dust at the feed and discharge ports is small. Materials: carbon steel, contact material 304 stainless steel, all 304 stainless steel models for customers to choose.

Its working principle is to use two high-speed rotating rollers to clamp the material in the middle, and then crush it by extrusion and grinding. This crushing method can effectively reduce the hardness of the material, improve its crushing efficiency, can achieve continuous operation, improve production efficiency; It can not only control the size of the discharge particle by adjusting the distance between the rollers; Dust pollution in the production process can also be reduced by adding dust removal systems.

| Device name | Model | Crush capacity | Power | Feed particle size | Fineness |

| Urea pulverizer | SHG600 | 3~4ton/h | 5.5KW*2 | ≤5mm | ≤0.2-0.5 mm |

| SHG800 | 5~6ton/h | 7.5KW*2 | ≤5mm | ≤0.2-0.5 mm |

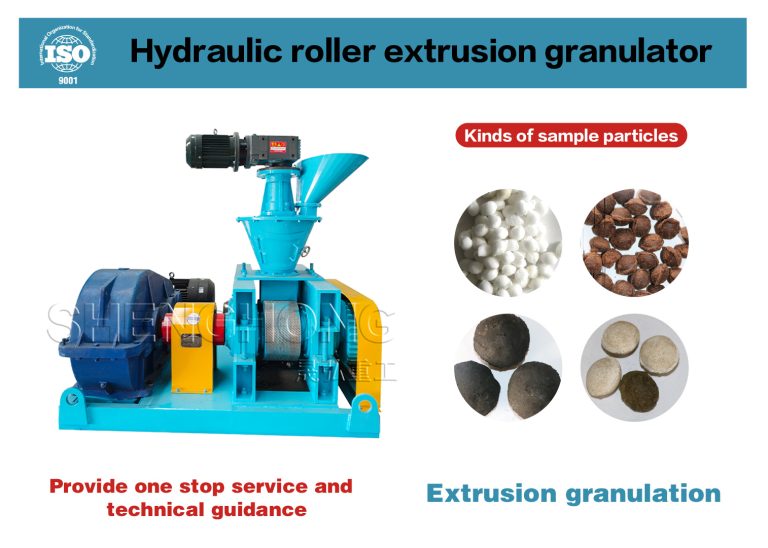

Applications and Functions The hydraulic roller granulator adopts dry roll pressing technology to compress the powder material with water content ≤8% into a sheet or…

Applications and Functions New organic fertilizer special granulator, used for livestock manure, urban sludge, and domestic waste processing organic fertilizer one of the granulation equipment.…

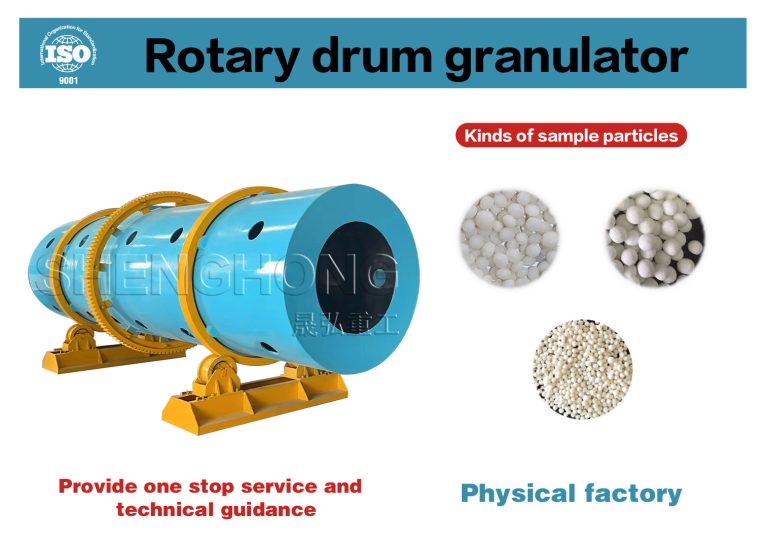

Applications and Functions The simplified machine adopts a special rubber plate lining or acid-resistant stainless steel lining plate, which realizes automatic scar removal and tumor…

Horizontal Fermenter Use The horizontal fermenter is suitable for the treatment of different feces, carcasses, kitchen waste, domestic sewage, and silt. As long as the…

Leave your needs, we will get in touch with you as soon as possible!