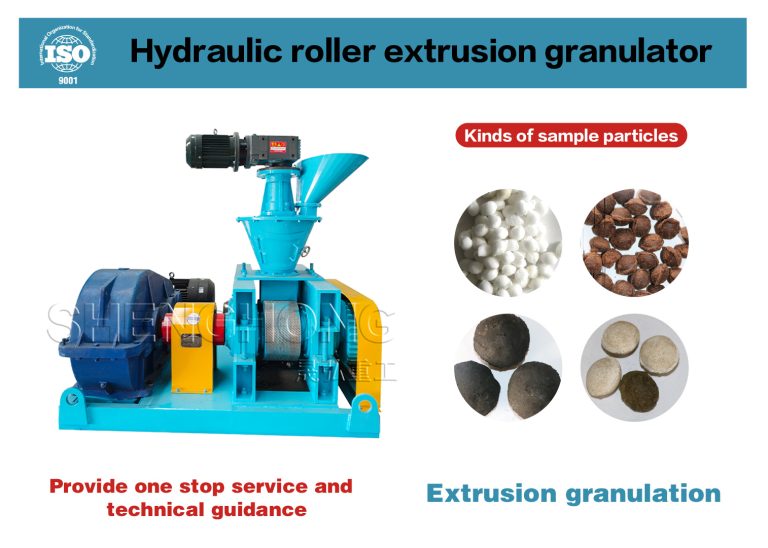

The double roller extrusion granulator is an efficient equipment that directly compresses powder raw materials into uniform particles through twin-roller extrusion molding technology. It is widely used in chemical industry, metallurgy, pharmaceutical, agriculture (fertilizer/feed) and other fields. It is suitable for the granulation needs of various dry powder or wet powder materials. It has the characteristics of high pelletizing rate, uniform particles and easy operation.

The equipment shipped this time is strong and durable, suitable for processing a variety of materials, easy to operate and efficient and energy-saving. A comprehensive inspection is carried out before shipment to ensure that the equipment is in good condition and is packaged in reinforced wooden boxes.

If you need customs clearance assistance or document support during transportation, please communicate with us in advance. If you have any questions or needs after the equipment arrives, please contact our team and we will follow up the entire process. Thank you for your trust and look forward to cooperating with customers from more countries and regions!

| Model | SDZ-Ⅰ-1.0 | SDZ-Ⅰ-2.0 | SDZ-Ⅰ-3.0 | SDZ-Ⅰ-4.0 | SDZ-Ⅱ-1.0 | SDZ-Ⅱ-2.0 | SDZ-Ⅱ-3.0 |

| Capacity(t/h) | 1~1.5 | 1.5~2.5 | 2.5~3.5 | 3.5~4.5 | 1~2 | 1.5~2.5 | 2.5-3.5 |

| Power | 11KW | 18.5KW | 22KW | 45KW | 15KW | 18.5KW | 22KW |

| Mold specifications(Φ) | 150×220 | 150X300 | 186X300 | 300X300 | 150×220 | 186X300 | 300X300 |

| Feed particle size | ≦0.5mm | ≦0.5mm | ≦0.5mm | ≦0.5mm | ≦0.5mm | ≦0.5mm | ≦0.5mm |

| Finished product specifications(Φ) | 2.5~10 | 2.5~10 | 2.5~20 | 2.5~30 | 2.5~10 | 2.5~10 | 2.5~20 |

| Reducer model | ZQH350 | ZQH400 | ZQH400 | ZQH500 | Special | Special | Special |

| Material | 2%~8% | 2%~8% | 2%~8% | 2%~8% | 2%~8% | 2%~8% | 2%~8% |

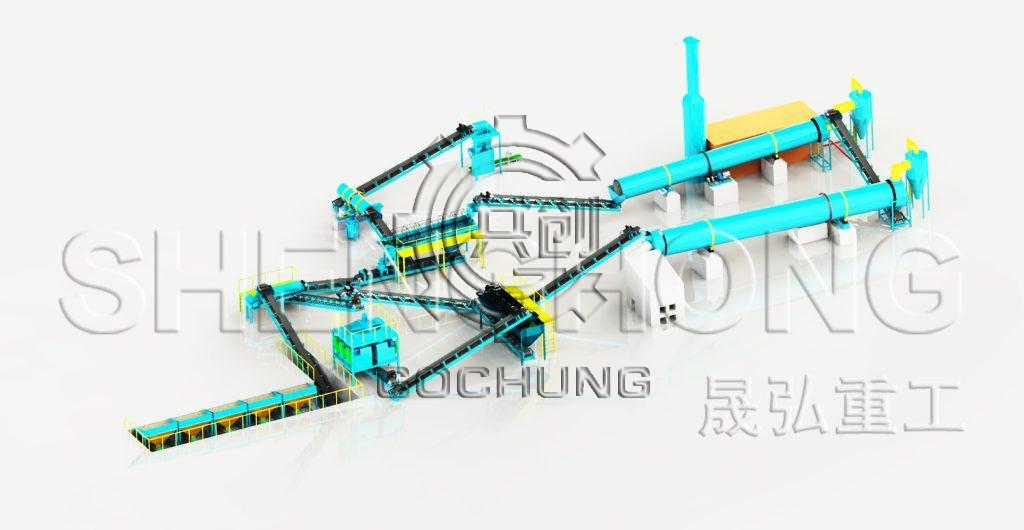

How to use a double-roller granulator to produce granules with greater capacity?

Choose a double-roller granulation production line to meet your needs. Its production capacity can reach 1-100t/h, including one-stop service from crushing, mixing, granulation, screening, crushing to packaging.

This production line has the advantages of high production efficiency, good particle strength, energy saving and environmental protection, and is widely used in chemical, fertilizer, feed and other industries. The material is evenly fed through the feeding system and enters the counter-roller extrusion device.

Under the strong extrusion force of the two relatively rotating rollers, the material is pressed into flakes and broken into particles. Subsequently, qualified particles are screened out through a screening system, and unqualified particles are returned for reprocessing.

Zhengzhou Shenghong Heavy Industry Technology Co., Ltd.

Email: [email protected]

WhatsApp: 0086 15838200712

Wechat: +86 15838200712

Applications and Functions The hydraulic roller granulator adopts dry roll pressing technology to compress the powder material with water content ≤8% into a sheet or…

Applications and Functions New organic fertilizer special granulator, used for livestock manure, urban sludge, and domestic waste processing organic fertilizer one of the granulation equipment.…

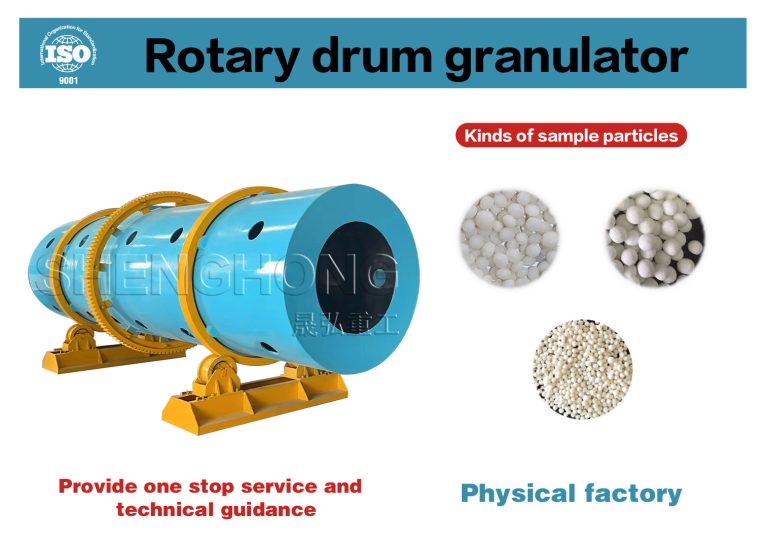

Applications and Functions The simplified machine adopts a special rubber plate lining or acid-resistant stainless steel lining plate, which realizes automatic scar removal and tumor…

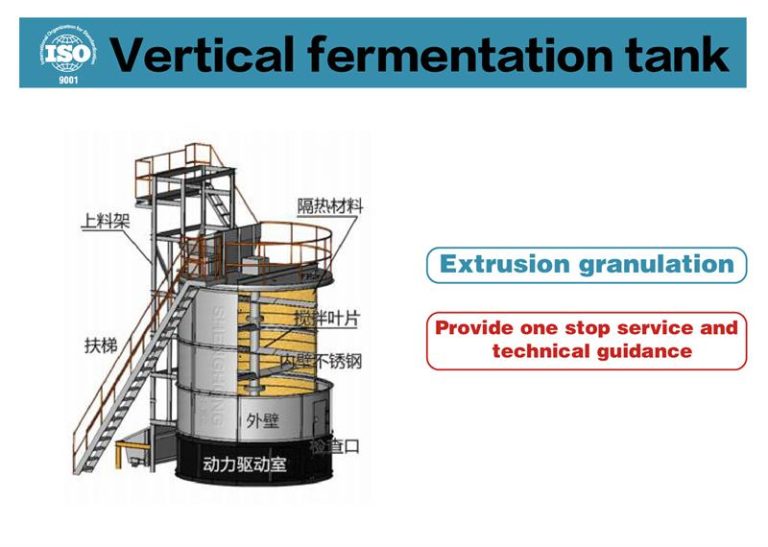

Horizontal Fermenter Use The horizontal fermenter is suitable for the treatment of different feces, carcasses, kitchen waste, domestic sewage, and silt. As long as the…

Leave your needs, we will get in touch with you as soon as possible!