The roller granulation production line has low investment, quick results, good economic benefits, one-time molding and dry granulation. It is suitable for the manufacturing of various raw materials such as compound fertilizers, medicines, chemicals, and feeds. Granules, the product granulation rate is high. It can produce compound fertilizers of various concentrations and types (including organic fertilizers, inorganic fertilizers, biological fertilizers, magnetic fertilizers, etc.). Especially for the granulation of rare and ammonium bicarbonate series compound fertilizers.

1、Batching machine

ammonium nitrate, ammonium oxide, ammonium sulfate, ammonium phosphate (beryllium phosphate, diphosphate, heavy calcium, ordinary calcium), potassium chloride (potassium sulfate) and other raw materials are equipped in a certain proportion.

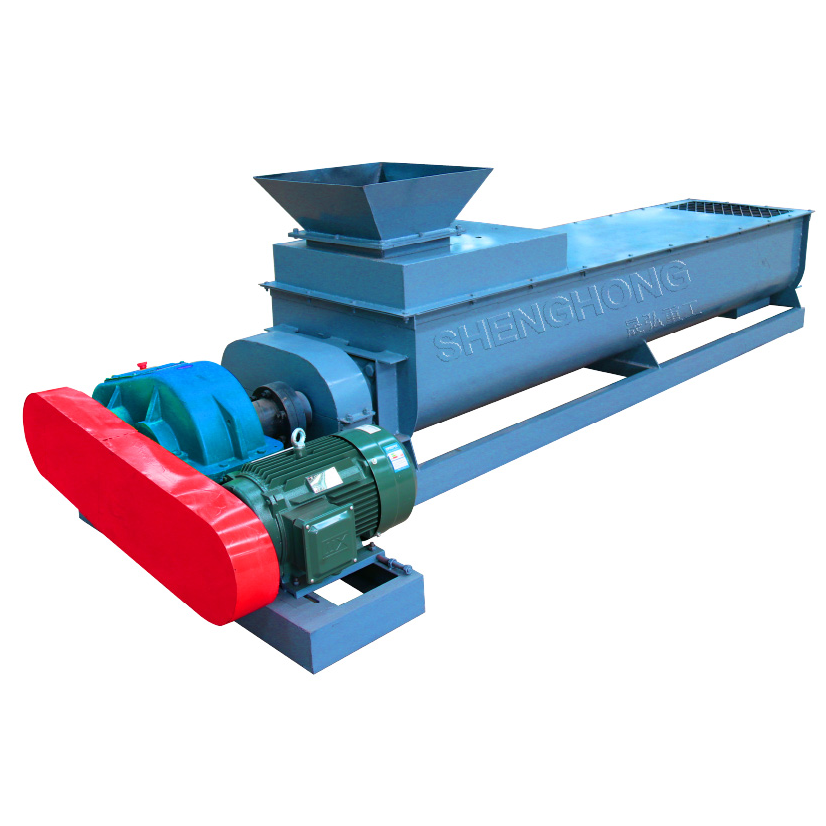

2、Mixing machine

Stir the prepared raw materials evenly to improve the uniform fertilizer content of the fertilizer particles as a whole. It widely occurs in chemical industry,pharmaceutic industry, food processing plant, architectural material industry and other fields.

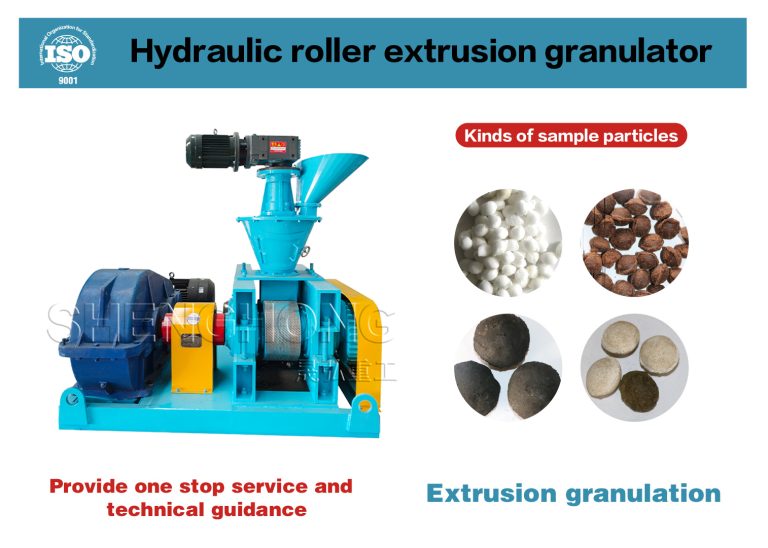

3、Granulating machine

Send the uniformly stirred raw materials into the transfer granulator for granulation.It is a molding machine that can make material to a specific shape. It is also one of the key equipment in compound fertilizer industry. Moreover, this machine has good appearance quality, corrosion and wear resistance, low energy consumption, long service life, simple operation and maintenance, etc.

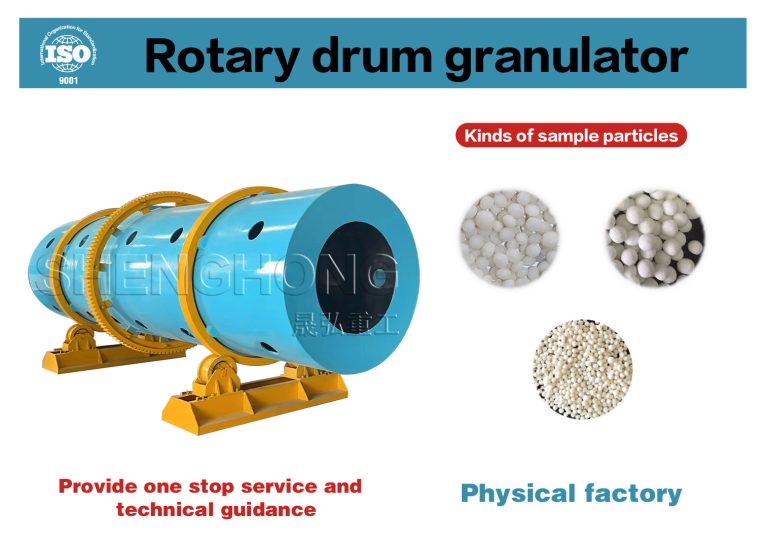

4、Drying machine

Send the granules made by the granulator into the dryer to dry the water contained in the granules to increase the strength of the granules and facilitate storage.

5、Cooling machine

The temperature of the dried fertilizer particles is too high and it is easy to agglomerate. After cooling, it is easy to bag, store and transport.

6、Screening machine

Classify the cooled particles, unqualified particles are crushed and re-granulated, and qualified products are screened out.The rotary screening machine is commonly used in compound fertilizer production, which is mainly used for the separation of finished products and returned materials, but also achieves the classification of granules. Besides, the machine has easy maintenance, simple structure, easy and smooth operation, which is the ideal equipment in compound fertilizer production.

7、Coating machine

The qualified products are coated to increase the brightness and roundness of the particles.Rotary coating machine consists of screw conveyor, rotary cylinder, oil pump, motor, reducer, and gears. It can effectively prevent the agglomeration of compound fertilizer. The inner cylinder consists of polypropylene or stainless steel with good corrosion resistance.

8、Packaging machine

Bag the film-wrapped particles, that is, the finished product, and store them in a ventilated place.The automatic quantitative packaging machine, which includes single bucket packaging scale and double one, is a mechanical device for quantitative weighing and packaging of granule and powder shape of bulk materials.

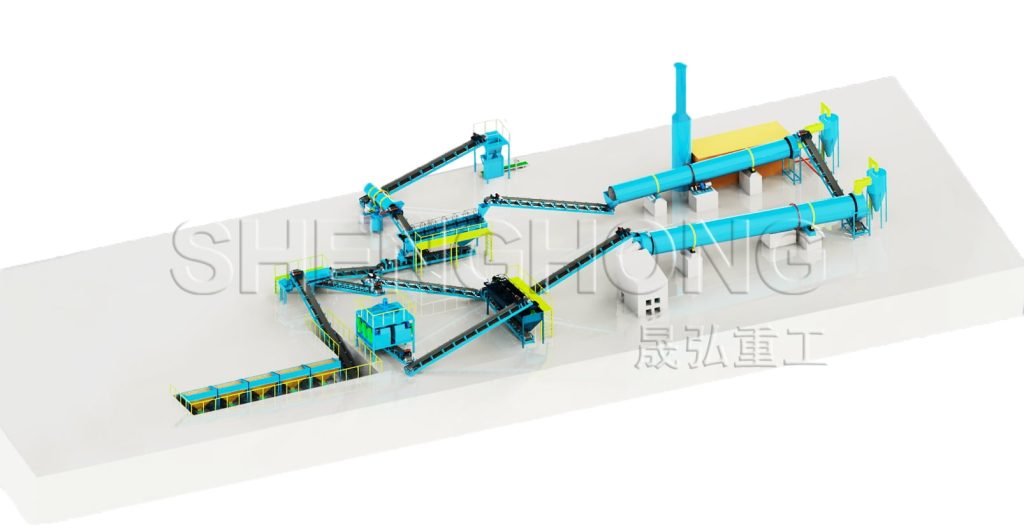

Roller production line process:

Applications and Functions The hydraulic roller granulator adopts dry roll pressing technology to compress the powder material with water content ≤8% into a sheet or…

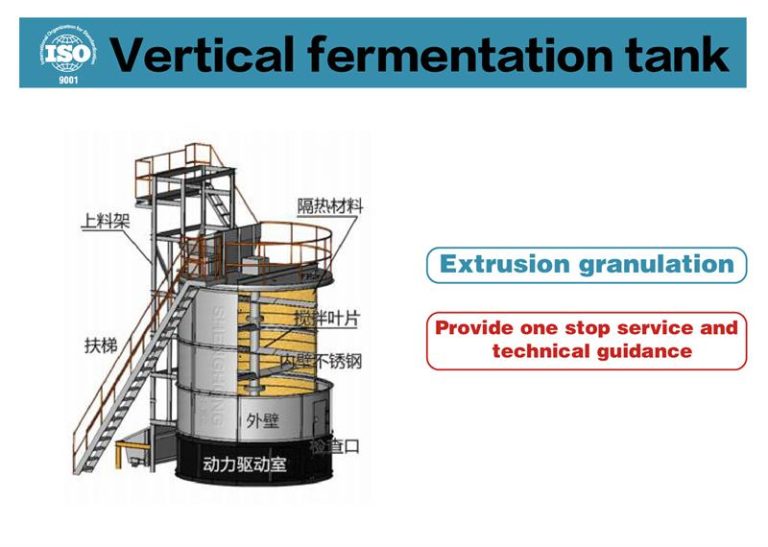

Applications and Functions New organic fertilizer special granulator, used for livestock manure, urban sludge, and domestic waste processing organic fertilizer one of the granulation equipment.…

Applications and Functions The simplified machine adopts a special rubber plate lining or acid-resistant stainless steel lining plate, which realizes automatic scar removal and tumor…

Horizontal Fermenter Use The horizontal fermenter is suitable for the treatment of different feces, carcasses, kitchen waste, domestic sewage, and silt. As long as the…

Leave your needs, we will get in touch with you as soon as possible!