It is an efficient material crushing equipment; It is composed of two cylindrical cages perpendicular to each other, and each cage is equipped with blades and crushing wheels, through high-speed rotation and impact to achieve the crushing of materials.

The principle of the double cage crusher is that the material first enters a cage of the crusher, is impacted and cut by the blade and the grinding wheel, and then enters another cage, is impacted and cut again. Such repeated impact and shear make the material gradually crushed, refined and evenly mixed. In addition, the double-cage crusher can pretend to be a dust removal system, purify the generated dust, and meet the emission standards, so it has become one of the important equipment in the powder processing industry.

| Specifications | Power (kw) | Capacity (t/h) | Outline dimension (length*width*height) |

| 500 | 5.5/7.5 | 3-4 | 1120X1120X1280 |

| 600 | 11/7.5 | 4-6 | 1350X1300X955 |

| 800 | 18.5/18.5 | 7-10 | 1630X1750X1500 |

| 1000 | 30/30 | 10-13 | 2025X2100X1566 |

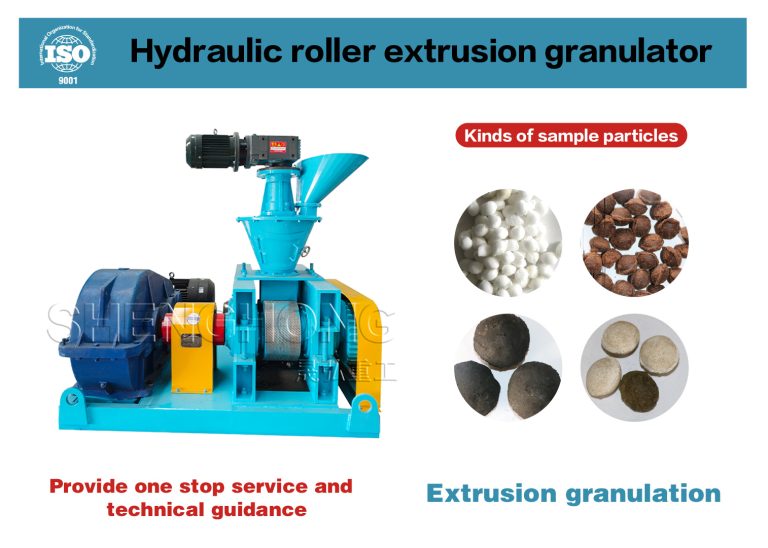

Applications and Functions The hydraulic roller granulator adopts dry roll pressing technology to compress the powder material with water content ≤8% into a sheet or…

Applications and Functions New organic fertilizer special granulator, used for livestock manure, urban sludge, and domestic waste processing organic fertilizer one of the granulation equipment.…

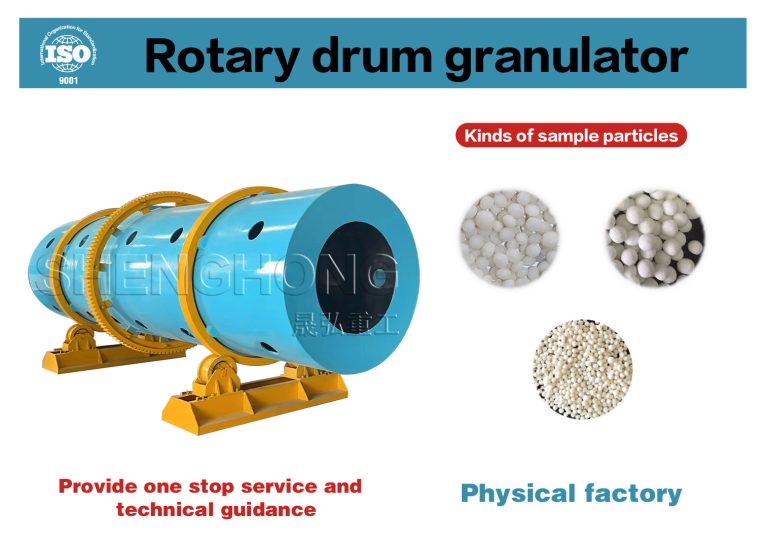

Applications and Functions The simplified machine adopts a special rubber plate lining or acid-resistant stainless steel lining plate, which realizes automatic scar removal and tumor…

Horizontal Fermenter Use The horizontal fermenter is suitable for the treatment of different feces, carcasses, kitchen waste, domestic sewage, and silt. As long as the…

Leave your needs, we will get in touch with you as soon as possible!