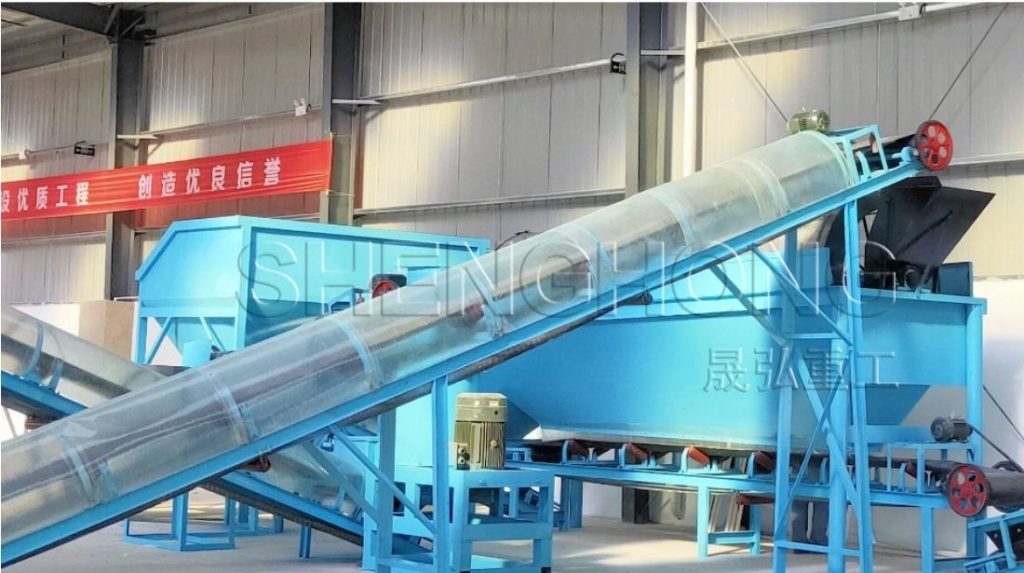

Last week, we sent an organic fertilizer powder production line to Vietnam. This organic fertilizer powder production line includes forklift silo, semi-wet material crusher, screening machine and packaging machine. The customer took the initiative to contact our business through the recommendation of a friend, and asked our salesman about the organic fertilizer granule production line. After our salesperson carefully consulted the customer's needs, he recommended the organic fertilizer powder production line to the customer. The customer did not accept the recommendation of our salesman at first. Later, after we carefully analyzed the specific needs of the customer, the customer accepted the recommendation of our salesman and purchased the organic fertilizer powder production line.

Powdered organic fertilizer refers to the fertilizer produced by fermenting organic raw materials in a certain proportion without forming particles. The production process of powdered organic fertilizer is as follows:

1. Ingredients before fermentation: When the water content of the raw material is too low, water or livestock and poultry urine should be added to increase the water content. When the water content of the raw material is too high, solid-liquid separation should be adopted, or the method of adding auxiliary materials should be used to reduce the water content. The auxiliary materials can be straw, peanut shells, and other plant residues. The final moisture content should reach 45%-50%.

2. After the ratio of the raw materials is good, it should be fully stirred and put into the stacking tank or stacked on the level into strips, 2 meters wide and 1 meter high. Or decide the size of the stack according to the existing turner.

3. Add bacterial strains: The bacterial strains and bacterial residues are prepared in a ratio of 1:5. About 1 kg of bacterial strains are added for every 15 tons of fecal raw materials, and evenly sprinkled on the surface of the pile, the purpose is to increase the beneficial bacteria and improve the fermentation speed. .

4. Start fermentation: use a crawler-type turner in the open field, and use a trough-type turner for trough fermentation to turn over the pile. When the temperature reaches 60°C or more, turn over and toss every 2 days. After 10 days of fermentation at 60°C, the fermentation work is completed.

5. Crushing of raw materials: In order to avoid agglomeration during storage, the fermented and decomposed raw materials are also subjected to pulverization treatment. A special organic fertilizer crusher is used to finely pulverize the raw materials. After the first pulverization, the raw materials need to be pulverized once. Screening, the incompletely crushed sieve is screened out for secondary crushing, and finally a uniform and fine organic fertilizer is obtained.

6. At this point, the whole process of powdered organic fertilizer has been processed and can be packaged and sold.