Enter the factory training class in March 2024 and learn the system operation of packaging equipment and fully automatic batching equipment.

First of all, we need to understand the basic composition and working principle of packaging equipment. Through vivid examples and illustrations, the functions and operation methods of each component are analyzed in detail, and the core knowledge of packaging equipment is mastered.

Learn how to accurately control the proportion of ingredients, improve production efficiency and ensure product quality, and share some practical operating skills and experiences to make customers more comfortable in actual operations.

There are also some interactive sessions, including questions and answers, quizzes, etc., so that you can better consolidate the knowledge you have learned, exchange experiences with other students, better serve customers, and let customers have a deeper understanding of the product.

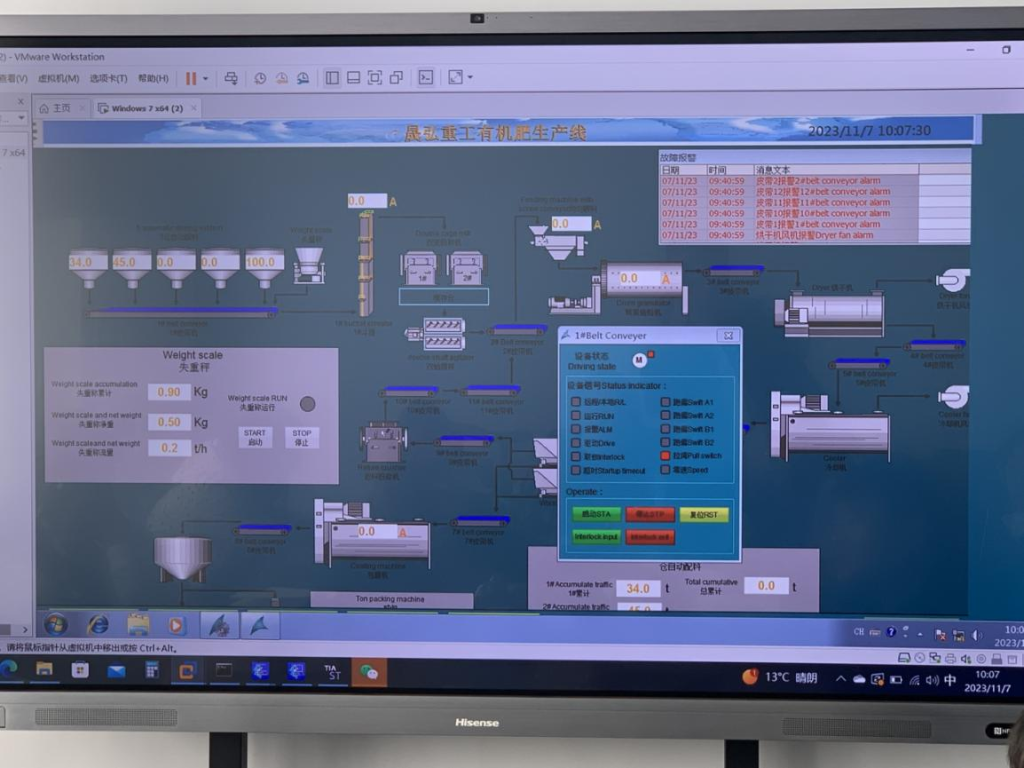

The fully automatic batching system is an important part of the modern industrial production line. It can automatically complete the precise proportioning and mixing of various raw materials. First, we need to put various raw materials into different silos of the system. Then, through the set formula, the system will automatically calculate the weight or volume required for each raw material, and control the corresponding silo for unloading. At the same time, the system will also monitor various parameters in the batching process in real time, such as weight, speed, etc., to ensure the accuracy and stability of the batching. After completing the batching, the system will automatically output the mixed materials to the next production link. Compared with the traditional manual batching method, the fully automatic batching system has higher accuracy and efficiency, and can greatly improve the automation level and production efficiency of the production line. In addition, it can also reduce the impact of human factors on the ingredients process and improve product stability and consistency.